| products | download | news | employment | contact |

|

|

|

| products |

| automation |

| robot systems |

| in-mould labelling |

| sir 1013 |

| sir-m 1015 |

| lps 1007 |

| samples |

| projectmanagement |

| consultancy |

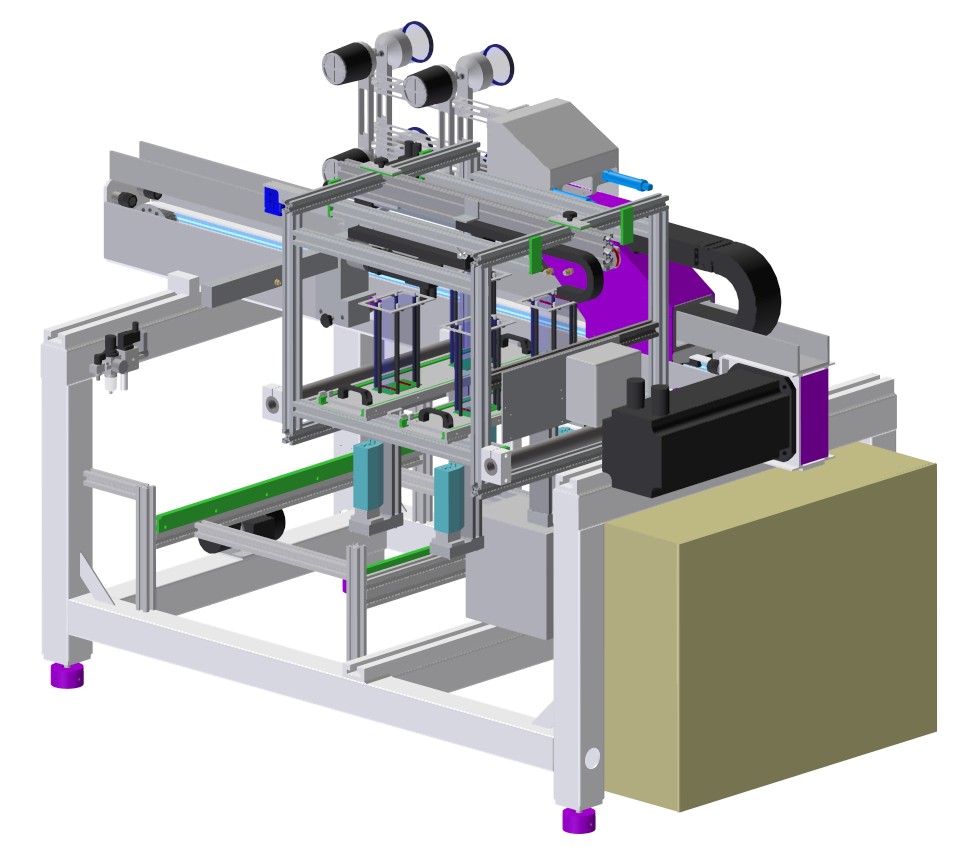

The SIR is built for speed and flexibility. Because of this flexibility (it can be adjusted within 2 hours from production with for instance an eight-cavity rectangular lid to a four-cavity round cup, the same goes for stacked moulds) you will be able to accept purchase orders that run much shorter. With the SIR you don't have to amortize the entire automation on just one contract.

Function

The purpose of the SIR to feed and position the labels into the mould of the injection moulding machine and simultaneously take out the finished products. The SIR was designed for speed and to be able to handle labels with a wide range of shapes, sizes and quantities (cavities) and is very suited for the production of high volumes at very short cycle times.

The SIR is equipped with a product set, if you wish to use the SIR with another product (and therefore another shape/size label) you will not need a new SIR, only a new product set.

Possible options:

- second robot arm including second magazin for production with stacked moulds

- telescopic robot arm (also available for stacked moulds)

- stacker (for stacked moulds one stacker will suffice but adding another on the other side is possible)

- conveyor belt

- quality control with sensors or camera (vision)

Download

- Datasheet (pdf)

Picture

Technical specifications

Dimensions

1250mm x 2525mm, hight 1750mm (without product set).

Label-area

The horizontal area available for the labels to be placed in is 500mm x 500mm. Label-area divided by the size per label gives you the maximum number of cavities possible with this size of label.

Speed

Maximum speed (empty) of servo driven robot arm approximately 9 m/s (32,4 km/h or 20,13 miles/h).

Acceleration

Maximum acceleration (empty) of servo driven robot arm approximately 10g (100 m/sē).

Controle paneel (touch screen)

Adjustable speed, positions, product set data and more.

Label-feed

One cassette filled with a number of stockpiled labels (depending on the number of cavities in the mould). The empty cassette has to be exchanged manually.

Labelpositioning

Thanks to our patented positioning units the positions of the labels can be adjusted very easily and very accurately.

Cycle time

Estimated time take out only with 4-cavity mould; below 1 second.

Time for product set exchange

Approximately 120 minutes (also with stacked moulds).

Possible injection moulding machines

All globally well known brands are possible but also most other brands.

Air

The SIR needs 6 bar of dry clean air. A vacuum pump is included.

Power

380V.

Electro-static charge

To ensure that the labels, after having been placed into the mould, will stay on the designated place, an electro-static charge device is included.

These specifications are standard and will fit most configurations. If necessary, adjustments can be made to fit your exact needs.

|