| products | download | news | employment | contact |

|

|

|

| products |

| automation |

| robot systems |

| in-mould labelling |

| sir 1013 |

| sir-m 1015 |

| lps 1007 |

| samples |

| projectmanagement |

| consultancy |

In-Mould Labelling (IML) is a variant of insert moulding where a plastic label (for decorating a plastic product, container, bucket, cup, etc.) is inserted into the mould. After plastic has been injected into the mould, the previously inserted plastic label becomes an integral part of the product. With this technique it is possible to decorate plastic products with photo quality labels.

IML should not be confused with In-Mould Decoration (IMD). IMD is a technique where a plastic foil is run through the mould. On the foil there is a picture which, after the mould has closed and reopened, has become part of the product. The picture is no longer on the foil but because the foil does not become part of the product, this is nog insert moulding. IMD is used for for instance decorating the fronts of cellphones.

Almation is a specialist on IML and has several standard solutions available for you. Should you require something for which our standard solutions are not suited, Almation is very capable to provide you with a custom-made solution for your IML product.

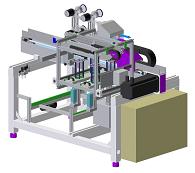

SIR 1013

Especially suited for production at extreme high speeds. Read more...>

SIR-M 1015

Only suited for production with one to two cavity moulds. Read more...>

LPS 1007

IML in combination with a standard 3-axis servo robot. Read more...>

Samples

To illustrate the possibilities of IML we have selected some samples of a few very different products where IML was used. Read more...>

Link

- Contact Almation

|